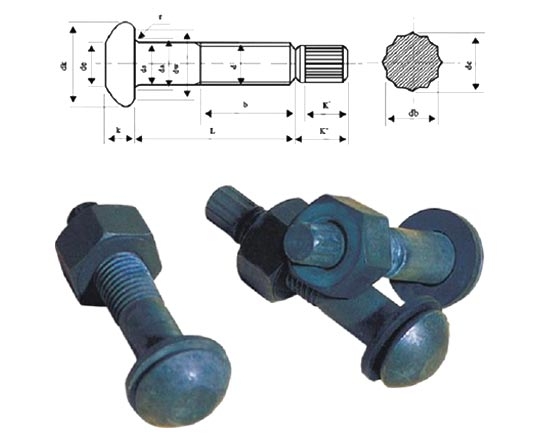

GB/T 3632~363 Steel structure adopts high strength torsional shear bolt type Size

Functions: torsional high strength shear type is the advanced large hexagonal high-strength bolt and high strength bolt, belonging to a kind of standard parts. After first tight and end tight construction, it is generally used for permanent connection.

Application: suitable for railway and Highway Bridge, boiler steel structure, industrial buildings, high-rise buildings, tower mast structure, hoisting machinery and other friction type high strength bolt connection.

|

Thread specifications -d |

M16 |

M20 |

M22 |

M24 |

M27 |

M30 | |

|

Screw pitch P |

2 |

2.5 |

2.5 |

3 |

3 |

3.5 | |

|

da |

max |

18.83 |

24.4 |

26.4 |

28.4 |

32.84 |

35.84 |

|

ds |

max |

16.43 |

20.52 |

22.52 |

24.52 |

27.84 |

30.84 |

|

min |

15.57 |

19.48 |

21.48 |

23.48 |

26.16 |

29.16 | |

|

dw |

min |

27.9 |

34.5 |

38.5 |

41.5 |

42.8 |

46.5 |

|

dk |

max |

30 |

37 |

41 |

44 |

50 |

55 |

|

k, |

nom |

10 |

13 |

14 |

15 |

17 |

19 |

|

max |

10.75 |

13.9 |

14.9 |

15.9 |

17.9 |

20.05 | |

|

min |

9.25 |

12.1 |

13.1 |

14.1 |

16.1 |

17.95 | |

|

k' |

min |

12 |

14 |

15 |

16 |

17 |

18 |

|

k" |

max |

17 |

19 |

21 |

23 |

24 |

25 |

|

r |

min |

1.2 |

1.2 |

1.2 |

1.6 |

2 |

2 |

|

db |

max |

11.3 |

14.1 |

15.6 |

16.9 |

19.3 |

21.4 |

|

min |

11 |

13.8 |

15.3 |

16.6 |

18.7 |

20.8 | |

|

dc ≈ |

12.8 |

16.1 |

17.8 |

19.3 |

21.9 |

24.4 | |

|

de ≈ |

13 |

17 |

18 |

20 |

22 |

24 | |

Mechanical behavior:

|

Grade |

Tensile strength |

Yield strengthσ0.2 |

Elongation δ5 |

Shrinking percentage Ψ |

|

σь |

Mpa |

% |

% | |

|

Mpa |

min | |||

|

10.9S |

1040~1240 |

940 |

10 |

42 |

|

8.8S |

830~1030 |

660 |

12 |

45 |

Loading force:

|

Thread specifications-d |

M16 |

M20 |

M22 |

M24 |

M27 |

M30 | |

|

Pressed force section mm2 |

157 |

245 |

303 |

353 |

459 |

561 | |

|

Pull force KN |

10.9S |

163~195 |

255~304 |

315~376 |

367~438 |

477~569 |

583~696 |

|

8.8S |

130~162 |

203~252 |

251~312 |

293~364 |

381~473 |

466~578 | |

Materials for steel bolt and nut, flat pad:

|

Type |

Performance level |

Thread specifications |

Materials |

|

Bolt |

10.9S |

M12~M24 |

20MnTiB |

|

M27~M30 |

35VB | ||

|

8.8S |

M12~M16 |

35# | |

|

M20~M24 |

20MnTiB | ||

|

M27~M30 |

35VB | ||

|

Nut |

8H 10H |

M12~M30 |

35# |

|

Washer |

35~45 HRC |

12~30 |

45# |

Chemical component:

|

Materials |

C% |

Si% |

Mn% |

Ti% |

V% |

B% |

P% |

S% |

|

20MnTiB |

0.17~0.24 |

0.17~0.37 |

1.30~1.60 |

0.04~0.10 |

0.0005~0.0035 |

≤0.035 |

≤0.035 | |

|

35VB |

0.31~0.37 |

0.17~0.37 |

0.50~0.90 |

0.05~0.12 |

0.001~0.004 |

≤0.04 |

≤0.04 | |

|

35# |

0.32~0.40 |

0.17~0.37 |

0.50~0.80 |

≤0.035 |

≤0.035 | |||

|

45# |

0.42~0.50 |

0.17~0.37 |

0.50~0.80 |

≤0.035 |

≤0.035 |

联系电话

微信号