Prefabricated steel villa

Prefabricated steel villa

1.STEEL STRUCTURE VILLA

Steel structure villa industrial production using a combination of standard components, it has many advantages: flexible design, cost control, construction period is short, fast and convenient way to pay, environmental protection, good shock resistance, safer, more flexible, more savings energy. Steel structure villa widely built in tourist attractions, the seaside resort around the house or other purposes. If you want to understand the benefits of more steel structure villa, please contact us, we will answer your questions in detail.

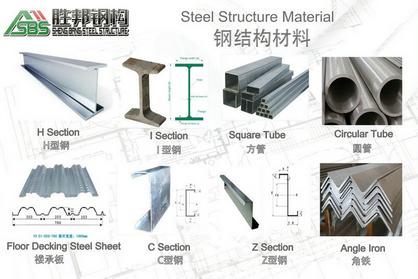

2、The detail material for the steel structure

1)Z-Section Sheet

Z steel is common cold bending thin-wall steel, whose thickness is commonly between 1.6-3.0mm, section heights between 120-350mm. Processing materials is hot rolled (paint), galvanized. It is processed according to perform standards. Z steel is usually applied in large steel structure factory building.

2)H section steel

H type steel is an economic efficient section material with optimized cross section area allocation and more reasonable ratio of strength to weight. It is named because of its letter "H" cross section. Since its different parts are of orthogonal configuration, h-beam has advantage of good bending capacity, simple construction, cost saving and structure light weight etc., has been widely used.

3)H-beam is divided into:

The flange wide type (HW)

The flange middle type (HM)

The narrow flange type (HN)

Thin-wall h-beam type (HT)

H section steel pile type (HU)

4)C steel was processed after hot rolling and cold bending. Its characteristics are: thin wall, light weight, good cross section performance, high strength (compared with the traditional steel) and can save 30% materials compared with the equivalent steel.

5)C type steel is widely used in purlin and wall beam steel structure building, also can combined into lightweight roof, carrier construction, etc. In addition, it can also be used for machinery and column, beam and arm light industrial manufacturing.

3.Product details

| Product Name | Prefabricated Steel Structure Warehouse | |

| Specification | Foundation | Concrete and Steel |

| Support | X or V types, angle steel or round tube | |

| Surface | Two layers and anti-rust paint | |

| Color | White, Grey, Blue, Green, etc | |

| size | Designed by your requirement | |

| Advantages |

1. Stable Construction | |

| Main component | Base materials | Cement and steel foundation bolts |

| Main frame | H beam (welded or hot rolled) | |

| Material | Q35B,Q345B | |

| Purlin | C purlin (C120-320) or Z Purlin (Z100-200) | |

| Bracing | Tie bar, lateral bracing, column bracing, knee bracing, etc | |

| Bolt | Normal bolt, high strength bolts, Galvanized bolt | |

| Roof & wall | Sandwich panel, steel corrugated sheet | |

| Door | Sliding door , rolling shutter | |

| Window | PVC window, aluminum-alloy Window | |

| Accessories | Skylight, ventilation, downpipe and galvanized gutter etc . | |

4、Transportation:

Steel structure is mainly composed of steel column, steel beam, steel frame and the rigid support and so on, so steel structure component volume is larger, The mainly transportation for export is as follow:

1)40'HQ and 40'open top container

In general, after customer order, our engineering technology department design the steel structures will be according to the 40 'HQ and 40' open top container inside size to design the shipment, in most cases, we use 40 'HQ and 40' open top shipping container shipment to pack steel structures.

2)Break bulk

At special circumstances, some large construction size will be more than 40 'HQ and 40' open top containers internal dimensions, we suggest customer use trucks, flatbed trailer etc to transport the large construction component to the pier from the factory, then ship by port lifting, so while booking space,customers should book the break bulk. We will cooperate with the customer to provide them the size and weight of the goods, in order to book a reasonable space.

Remark:

When components are shipped to the site, due to various reasons of transport may cause component deformation (generally for bending, damage to the paint film, etc.), can be in the scene to correct, at present the correction method is generally divided into cold straightening and hot straightening.

For bending component, do the mechanical gagging with oil pump, also can use flame (C2H2 and pure oxygen mixed) to the hot straightening, after correction, the paint film that damaged must be repaired.

5.Guidance installation

Shengbang Steel Structure Company can supply the guidance installation service.Usually steel structure building is a large installation engineering. If customers may need the professional technical engineer to supervise the installation on site overseas, the customer must to inform before 1 months from leave the China . But customer should coordinate with us for following aspects:

Customer should provide:

1) Translator or assistant on site.

2.)All costs raised including:

A. visa fee

B. Round trip flight ticket

C. Accident insurance for the supervisor during the period

D. Accommodation

E. Daily meals

F. Internet

G. Local traffic fee (if any)

3) The customer should pay the engineer with supervision fee, which can be negotiated and decided by both.

4)Customer has the responsibility to provide necessary security system to protect the supervisor, especially in some unrest countries.

There have some guidance installation picture:

6、Advantage:

1)Quick and easy to assemble

2)Dry construction and environmentally friendly.

3)Light houses with strength structure

4)Excellent capacity of water proof, heat and sound insulation.

5)Materials 100% recyclable

6)Convenient to take apart and install.

7)Dry construction condition; no pollution; no waste.

8)During the construction, total saving 1/6 of CO2 Emissions, 1/6 of natural resources, 1/6 of natural energy and 9/10 of water using. Save labor cost on site.

9)The building self-weight is only 1/4 of brick-concrete structure.

10)Galvanized steel is 100% recyclable.

11)Fiber glass insulation filling in the roof is greatly superior to the brick structure on the effect of insulation and soundproof.

7.FAQ

1) Why choose the steel structure?

*Steel has the higher strength.

* 80% recyclable, Steel is the most recycled material in the world.

* No warping, no cracking, no chemical treatments.

* Stronger connection.

* Lower transport costs due to lightweight frames.

* Steel frames will not burn, fire proof.

* Lightning will not affect a steel framed house since steel creates a positive earth. Lightning energy is conducted straight to the ground.

* Each steel structure is a independent engineered.

2)Can I customize my house?

Yes. We have experienced and professional engineers and designers, who will help you to design the house according to your taste and needs.

3)What is the basic information of container house supplied by client?

We often get inquires for quotation from customers who even have no idea about the difference between flat pack container house with sandwich panel and modified container house. It always makes things complicated. Actually, we can provide you with quotation quickly but only when the client supply basic information as the following:

* Construction area, the quantity of containers house needed.

* Layout of the project.

* Usage of container house. (for labor house, container hotel, storage, container office or others)

* Local environment, weather and landform.

* With bathroom and toilet or not.

* Requirements for decoration or not.

* With electricity or not. Requirements for electricity are designed according to the plan.

FOSHAN SHENGBANG STEEL STRUCTURE CO., LTD

Add:Pingtang Industrial Park, Shipeng Village, Shishan Town, Nanhai District,

Foshan, Guangdong Province, China

Tel:0086-757-63323396 0086-18900873268 Fax:0086-757-81196682

Tel