Guangya steel villa

Guangya steel villa

2、Product Detail information

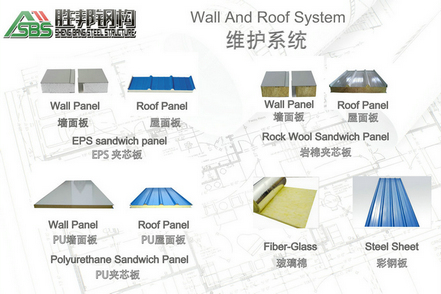

1)Steel Structure Panel material

The steel structure panel material included EPS sandwich panel,Rock wool sandwich panel,PU sandwich panel,fiber-glass ,steel sheet.

Steel structure panel material: including wall panel and roof panel

Sandwich core materials: EPS, PU, rock wool, glass wool

Thickness of sandwich panels: 50mm, 75mm, 100mm, 150mm

Single color plate material thickness: 0.376mm, 0.426mm, 0.476mm

1)FIBER GLASS

Glass wool adopts the most advanced centrifugation technique to fiber glass fibrosis, Such products has large amount and very thin glass fiber inside. Its total surface area is very large also, so as to strengthen the resistance of the air, making the air unable to flow and eliminating the air convection heat transfer; Similarly, huge friction decays vibration of the sound propagation carriers - air quickly, which ensures glass wool's good thermal insulation and sound absorption effect. It is also good material for sound absorption and noise reduction in steel structure building.

2)Rock Wool Sandwich Panel

Rock wool sandwich panel is not better than polystyrene and polyurethane sandwich panel with regard to sole weight, heat conduction, compressive strength, water absorption rate and other physical and mechanical properties. However, it can be used under the service temperature of 600℃. Besides, this type panel possesses the outstanding feature of being level A incombustibility, thus rock wool sandwich panel serviceable range is expanded to light weight construction materials for high requirement on fire-protection rating.

3.Product details

| Main structure | Steel Welded H Section |

| Purlin | C Section Channel or Z Section Channel |

| Roof Cladding | Sandwich Panel or Corrugated Steel Sheet with Fiber Glass Wool Coil |

| Wall Cladding | Sandwich Panel or Corrugated Steel Sheet |

| Tie Rod | Circular Steel Tube |

| Brace | Round Bar |

| Column & Transverse Brace | Angle Steel or H Section Steel or Steel Pipe |

| Knee Brace | Angle Steel |

| Roof Gutter | Color Steel Sheet |

| Rainspout | PVC Pipe |

| Door | Sliding Sandwich Panel Door or Metal Door |

| Windows | PVC/Plastic Steel/Aluminum Alloy Window |

| Connecting | High Strength Bolts |

| Packing | Can be loaded into 40ft'GP/HQ/OT, or 20 ft'container. |

| Drawing | We can make the design and quotation according to your requirement or your drawing |

4、Advantage:

1)Quick and easy to assemble

5.Transportation

Steel structure is mainly composed of steel column, steel beam, steel frame and the rigid support and so on, so steel structure component volume is larger, The mainly transportation for export is as follow:

1). Seaworthy

In general, after customer order, our engineering technology department design the steel structures will be according to the 40 'HQ and 40' open top container inside size to design the shipment, in most cases, we use 40 'HQ and 40' open top shipping container shipment to pack steel structures.

2).Package for the steel frame

If you want to use the 40 HQ container to transportation the whole steel structure product. You can do the steel frame to package ,use the cable wire to fix. But you must paid for the steel frame and baling charges.

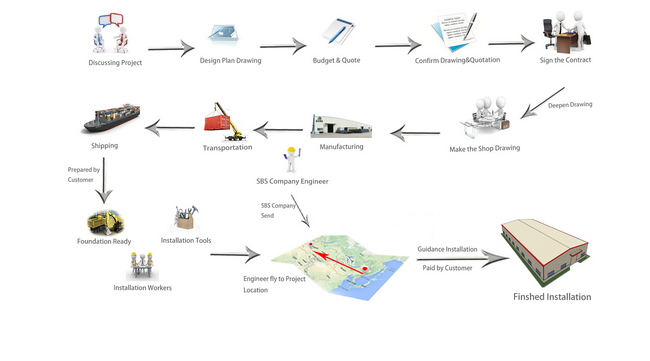

6、Service flow path:

Discussing Project——Design Plan Drawing——Budget & Quote——Confirm Drawing&Quotation——Sign the Contract——Make the shop Drawing——Manufacturing——Transportation——Shipping——Foundation Ready——Guidance Installation——Finshed Installation

7.Application range-Industry

Industry steel structure included warehouse,workshop,garage,hangar,platform.

Steel structure features of high fire resistance, strong corrosion resistance. Industry steel structure warehouse usually made of steel beams, steel columns, steel trusses and other components of the composition; each component using welds, bolts or rivets to connect. The usage scale includes large-scale workshop, or used for the warehouse, supermarkets, entertainment centers and modular steel structure garage.

FOSHAN SHENGBANG STEEL STRUCTURE CO., LTD

Add:Pingtang Industrial Park, Shipeng Village, Shishan Town, Nanhai District,

Foshan, Guangdong Province, China

Tel:0086-757-63323396 0086-18900873268 Fax:0086-757-81196682

Tel